Project Purpose

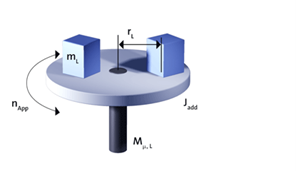

Design and execution of a rotary table for assembling wooden pallets.

Project Description

The project requirements were as follows:

- 0-180 degrees of table rotation

- Approximate weight of the assembly, including pallets: 100 kg (maximum)

- Gearmotor with encoder + brake

- Rotation time: 5 seconds/rotation for 180 degrees

- Controlled by PLC

- Use of a frequency converter

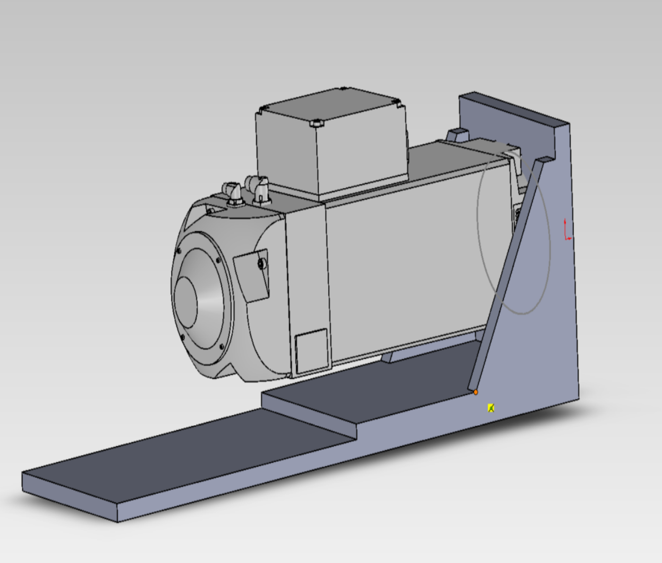

Following the configurations, our colleagues developed the following configuration:

- Gearmotor: 1 x G500-B450

- Motor: 1 x M550-P80/M4

- Converter: 1 x I950-C0.75/400-3

- Electromechanical Brake: 1 x Spring-applied brake 08 / 8.00 Nm

- Feedback: 1 x Incremental encoder IG1024-5V-T

- Brake Resistor: 1 x ERBM390R100W

Due to the shape of the table, the moment of inertia will influence the power required for the gearmotor to rotate the table. Therefore, a higher-power gearmotor, specifically 0.75 kW, provides a power reserve in case the weight exceeds 100 kg.

Lenze Product Codes::

- Gearmotor: 17064454 – G50BB145MSAK3N1C – M55BP080M045EFECC

- Converter: I95AE175F1AV10Z0QR