Client: STAMH SYSTEMS S.R.L.

End Beneficiary: KELLER LOGISTIC

The Keller Logistic Business Center integrates comprehensive services including controlled-temperature pallet storage, portioning/slicing, sorting, as well as options for packaging and labeling contents, along with A+ class office space for management and sales force, aimed at companies serving the food industry.

Electroglobal SA, in collaboration with STAMH SYSTEMS, carried out the project for the automation of the conveyor system at the logistics warehouse in Sînpaul, Mureș County.

Project Goal:

- Develop automation software for the entire conveyor system of the warehouse.

- Control automatic doors for the refrigeration chambers.

- Ensure communication between the conveyor system, the MFS (Material Flow System), and the 4 cranes.

Project Description:

The project involves developing a complete solution for the conveyor system, including:

- Development of the software application for the conveyor system.

- Design and delivery of electrical automation panels.

- Electrical installation of the automation equipment.

- Integration of automation into the warehouse management system.

The solution provided for this project includes several essential aspects, such as technical consultancy for the electrical project, manufacturing of automation panels, electrical installation of automation equipment, software application development for the conveyor system, creation of the graphical interface (operator panel) for operators, and commissioning of the conveyor system automation.

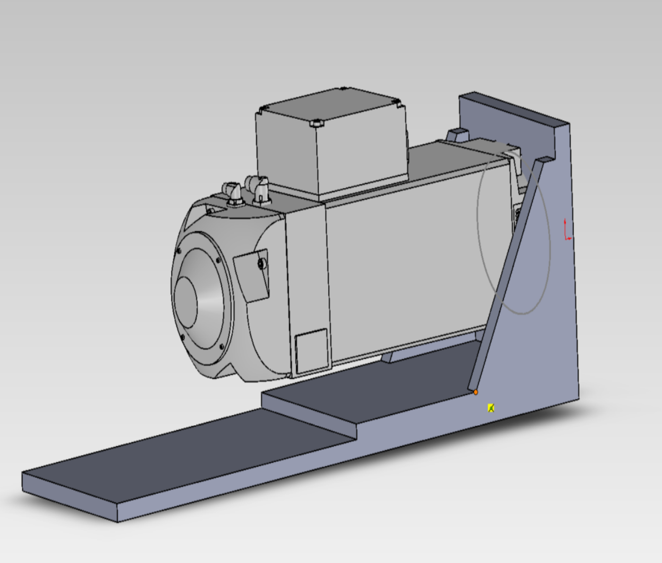

High-resolution tracking, precise speed adjustment, high-speed dynamics, short stop times, user-friendly oscilloscope functions, and stable operation under weak servomotor fields are crucial features that ensure the performance and reliability of the entire automation system. These features contribute to achieving optimal results and streamlining operations within the warehouse, thus ensuring efficient and integrated management of the conveyor system.

Equipment Used:

- Siemens Programmable Logic Controller, Simatic S7 1500-F series.

- Siemens I/O Modules, ET 200SP series.

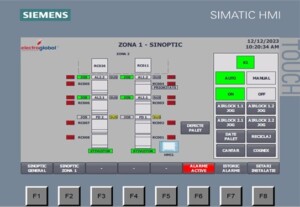

- Siemens HMI, KTP 700 and KTP 700F (Mobile Panel) series.

- Siemens Power Supplies, PSU series.

- Siemens AS-i Interface Power Supplies.

- SEW AS-i Modules for sensor status recovery and motor control.

- Schneider Protection and Switching Equipment, TeSys series.

- Phoenix Contact Connectors and Accessories.

Benefits:

- Reduced maneuvering times for pallet transport within the warehouse.

- Real-time visualization of each pallet’s position.

- Route modification for pallets via HMI.

- Selection of pallets not meeting the storage system’s requirements.

- Identification, weighing, measuring, and verification of pallets.

- Safety zone demarcation using safety barriers.

- Manual control of each conveyor.

- Optimization of tandem operation of conveyor assemblies, improving pallet transit times.

- Ensured transit of pallets between the two systems and to the final storage position via communication with the 4 cranes.

- Communication and information exchange with other systems in the installation.

- Security interlocks with peripheral systems (Cranes, Fire Protection System, Airlock, MFS).